|

What Is a Cable Assembly?

Here at Sherwood Electronics we are proud to be one of the UK’s leading manufacturers in Cable solutions for the OEM market. A question we are sometimes asked is “What Is a Cable Assembly” in this article we attempt to answer that question.

Cable Assembly

A cable assembly is also known as a cable harness, a wire harness, wiring assembly or wiring loom.

Generally speaking a cable assembly is a collection of cables or wires which transmit signals or electrical power in a designated sequence. The cables are often bound together by straps, or a common connection.

Cable Assemblies

Cable Assemblies are commonly used in automotive and electrical assemblies, as well as construction machinery, cable harnesses provide several advantages over loose wires and cables. For example, many aircraft, automobiles, and transport contain many masses of wires which would stretch over several kilometres if fully extended. By binding the many wires and cables into a cable harness, or cable looms the wires and cables can be better secured against the adverse effects of vibrations, abrasions, and moisture.

|

How are Cable Assemblies Made?

Cable Assembly manufacturing is an engineering skill that requires many years of experience to attain the highest level of quality.

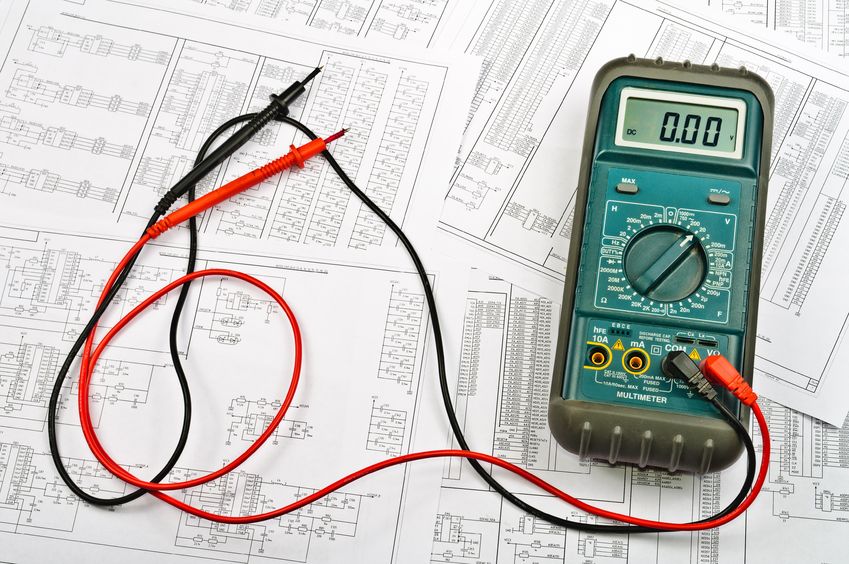

The first stage is to establish the Cable Assembly requirements, these are typically designed around the power or digital signal requirements of the various components within the area in which the wiring loom will operate. Once the needs are established a wiring diagram is produced to describe the schematic in the cable assembly.

|

|

A test or mock up cable assembly is manufactured, following the wiring diagram, cutting wires to length and terminating the ends with the correct connection.

Prior to terminating the individual cables, the ends of the wires are stripped to expose the metal (or core) of the wires, which are fitted with the correct electronic or digital terminal or specified connector housings.

Next, the cables are assembled and clamped together using special machinery or an assembly board, to form the cable harness. After fitting any protective sleeves, conduit, or extruded yarn, the harness is now ready for testing before fitting.

Much of the cable assembly process is now automated which has served to reduce cost and increase efficiency in cable assembly production. There remain many processes within cable assembly that still requires manual intervention due to the many different components often required within a typical wiring loom, such as:

• routing wires through sleeves,

• taping with fabric tape, in particular on branch outs from wire strands,

• crimping terminals onto wires, particularly for so-called multiple crimps(more than one wire into one terminal),

• inserting one sleeve into another,

• fastening strands with tape, clamps or cable ties.

It can be difficult to automate some of these processes and in some instances, manual production remains more cost effective than retooling and automation, especially with small batch sizes.

Pre-production can be automated in part. This affects:

• Cutting individual wires (cutting machine),

• crimping terminals onto one or both sides of the wire,

• partial plugging of wires pre-fitted with terminals into connector housings (module),

• Soldering wire ends (solder machine), and

• Pairing and twisted cables.

A testing board can be used to test the electrical and signal functionality of a cable harness, where harnesses can be tested individually or in quantity.

You minimise errors and risks with Sherwood Electronics

Outsourcing helps in reducing risks and other wiring errors that might take place because of the lack of training and experience.

At Sherwood Electronics, we have an extensive range of capabilities. Our qualified and experienced in-house experts leave no space for errors.

So, if you are interested in getting in touch with our specialists, you can simply leave us a message at our website //www.sherwoodelectronics.co.uk

Or call us at 0115 972 0100

|